EXACT

DESIGN

PRODUCTION LINES

Our main program is the solution of production processes so that the customer’s requirements are optimally met.

This activity includes the completion or innovation of production lines or their parts, including the activation and training of workers when handing over the machine to the customer.

SPECIAL HAND-HELD DEVICES

We design and supply our own solutions to customers who need special hand-held devices, or similar technological solutions that the market is not able to offer them.

We design such devices so that working with them is as comfortable and efficient as possible.

CNC MACHINING

For higher efficiency and flexibility, we have a milling center where we produce some parts for our projects, but also parts that our customers order from us. We produce these parts mostly on the basis of drawing documentation and 3D models that customers supply us.

In some cases, we produce according to the supplied samples, which we measure ourselves.

We machine parts in batches of one piece, as well as in series of thousands.

MACHINERY

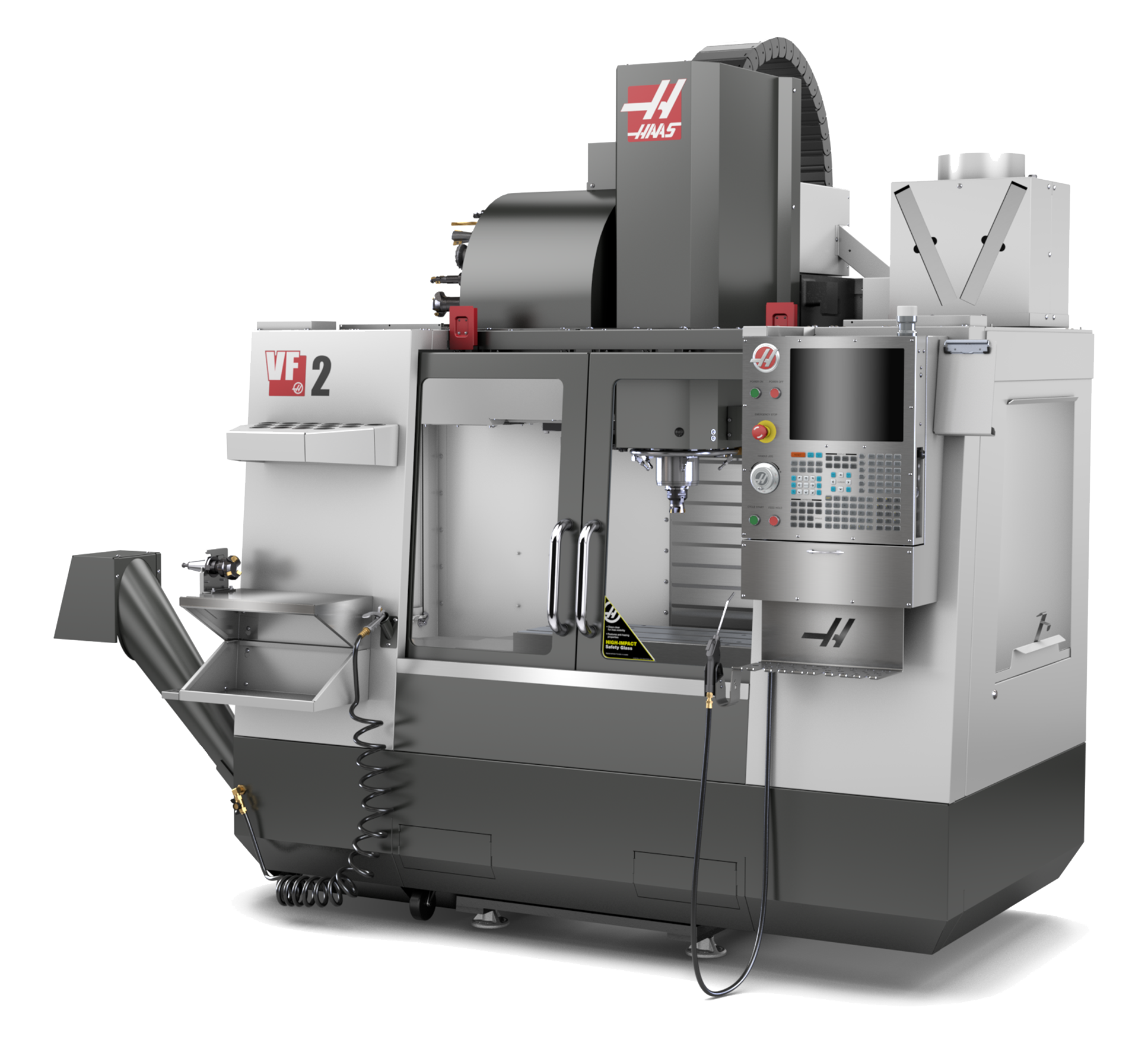

HAAS VF-2

Three-axis milling centre

Spindle: 22.4kW

Travels in the axis:

X Axis: 30 ” (762mm)

Y Axis: 16 ” (406mm)

Z Axis: 20 ” (508mm)

Tool and workpiece probes RENISHAW

The necessary tools, clamps, vices, clamping plates, etc..

Parts are manufactured based on technical drawings.

Considerable acceleration and simplification of production is facilitated by

3D models provided by certain customers. Provision of these files often leads to discovery of potential weaknesses that sometimes occur in the parts design.

For smooth continuity of production and possible delay shortening, both from customer’s side and from the production side point of view, direct communication with the designer of the particular piece has prooved to be invaluable. Any ambiguities are then solved quickly and without intermediaries.

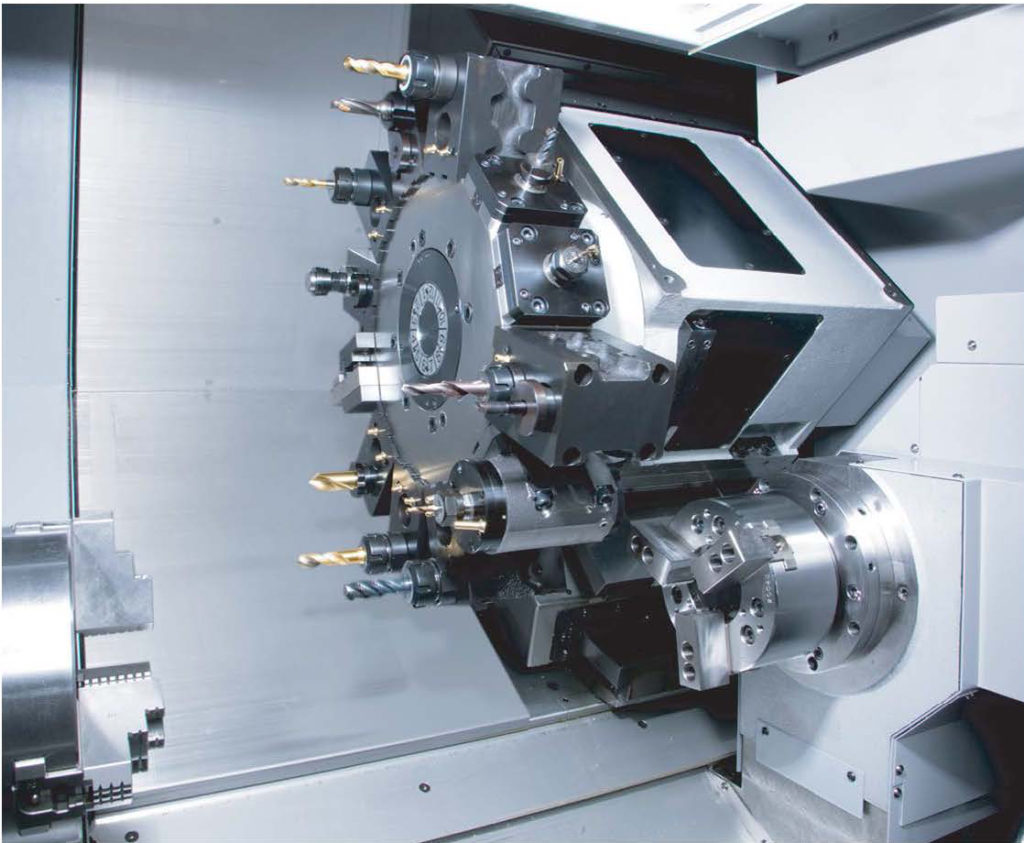

TSUGAMI M08SYE-II

Lathe with 4th axis, counter spindle and driven tools

Turning parameters:

Maximum turning diameter: 280 mm (11″)

Maximum rod diameter: 65 mm (2,56″)

Maximum turning length: 380 mm (14,96″)

A very rigid precise machine from a traditional Japanese manufacturer with 80 years of tradition. The machine is designed for demanding continuous production and for machining even difficult-to-machine materials.

The machine is equipped with a Y-axis, and all twelve tool positions can be equipped with driven tools, which makes it possible to perform not only turning operations, but the machine is also capable of milling, including shaped and shape-complex surfaces. Of course, drilling, reaming, and rigid threading off-axis, diagonally or perpendicularly to the axis. In addition, the machine is equipped with a counter-spindle, which enables automatic accurate transfer of the workpiece and machining from the other side. Thus the part can be complexly manufactured fully automatically.

About

The beginnings of our company date back to 2015, when trade was established under the name of Ing. Dominik Špinka. At that time, the business was already focused on the field of machining and the design of machinery.

Since 2018, we have been continuously transferring our activities from the trade to our company Exactum Bohemia.

At present, in addition to precision machining, our parts and workpieces of our customers, we are increasingly focusing on complete machine designs, including full automation, programming and recovery. These are mainly new production lines or retrofits focused on various production operations.

After handing over the machine to the customer, we provide training for its employees and, of course, the provision of post-warranty service for our lines.

We also focus on the design, manufacture and assembly of special hand-held devices that our market does not offer and that streamline the performance of our customers’ employees.

Our activities are supported by our own production at the milling centre. We cooperate with the production of other components and other necessary activities, such as modifications to the structure of materials and surface treatment, with quality suppliers that have been proven for years.

We plan to purchase a high-quality fully automated fourth-axis CNC lathe, tool-driven and sub-spindle in the near future to meet growing customer interest in our workpieces and to provide even better parts for our own designs.

Contact Us

Exactum Bohemia s.r.o.

Sportovní 223

280 02 Tři Dvory

CZECH REPUBLIC

+420 728 251 566

exactum@exactum.cz

CRN: 07063903

VAT: CZ07063903

Bank account: 2101431669/2010

BIC/SWIFT: FIOBCZPPXXX

IBAN: CZ4820100000002101431669

Exactum Bohemia

CNC Machining

Sportovní 223

Tři Dvory 280 02

+420 728 251 566

info@exactum.cz